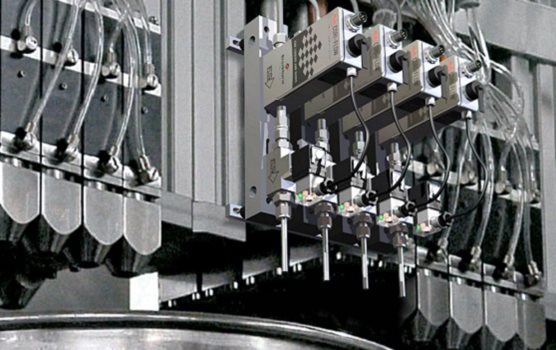

Chemical distribution is automated with the assistance of a dosing pump using a controlled dosing system. The dosing pump is an injector that injects a chemical or another substance into a jet of water, air, or vapor. Dosing pumps are usually small, but they do provide an extremely precise rate of flow for optimization. This dosing approach is used in a wide variety of industries and commercial applications, from treating wastewater to the food sector.

Dosing pumps are employed in industrial enterprises, horticulture, manufacturing plants, medical clinics, and mining activities, in addition to desalination and food processing. For example, to moderate the pH of a storage reservoir, a chemical injection pump could be used to supply a harsh reagent or an acid. It may be used to kill microorganisms like a chlorine pump.

Or it could be used to inject a predetermined volume of a drug into its container, making it an accurate way to ensure that each bottle has an equal amount of drug in it. A chemical dosing pump is designed to work in extreme conditions, such as extreme temperatures and very high pressures.

There are different types of dosing machines:

- Diaphragm (constant injection) pumps load and clear their compartments using a diaphragm, pistons, with gates on both the input and output. The cylinder is filled by pulling in the piston, and a predetermined amount of material is pumped at a predetermined speed, typically a proportion of the maximum flow rate.

- Diaphragm (pulse injection) pumps likewise employ the diaphragmatic principle, but rather than a uniform velocity, the substance is taken in and injected in bursts by a solenoid loop. The flow velocity is defined as the period between strokes. It’s much less precise than a continual injection pump, but it is easier to use and more economical.

- Dosing with peristaltic pumps is quite precise. An elastic curved tube allows the liquid to flow, and the stream is regulated by a roller just on the exterior that’s also moved by a mechanical structure. The substance in the tubes is pushed into the dosage pipe and the primary liquid flow as a result of this.

- Lobe pumps allow a specific amount of fluid to pass through the meshing gears. It isn’t as precise as diaphragm pumps, and it’s only good for highly viscous fluids that lubricate themselves to reduce wear.

The Bottom Line

Overall, dosing systems allow automated chemical dispersion into containers or pipes, without the need for user intervention, and with excellent precision at all times.